Company Efficiency Improvement Program – is a comprehensive program that includes process optimization in all or selected areas of the company. In the current crisis, this means actions of increased intensity but conducted in a specific way, i.e., to maintain growth potential despite optimizations and cost reductions! Our program combines the best elements from management optimization, waste identification and reduction, process reorganization, reducing operational gaps, eliminating bottlenecks, and increasing efficiency, creating a highly effective methodology for achieving growth.

The Efficiency Improvement Program covers all company processes: production, logistics, warehousing, office processes, purchasing, and sales, etc.

Methodology of the Company Efficiency Improvement Process:

- AUDIT: Analysis of the examined area, verification of key constraints and waste

- DIAGNOSIS: Visualization of processes, value stream examination, measurement of event sequences, identification of operational gaps, potential windows, and quick wins.

- POTENTIAL: Fundamental analysis, searching for synergies, reductions, reinforcements, and development of areas that impact efficiency.

- DEVELOPMENT PLAN: Conclusions, testing, action plan, and communication.

- IMPLEMENTATION: Implementation, modeling, and refining process cycles.

- MONITORING: Observation and monitoring.

- SMART: Verification, adjustment.

- CHANGE MANAGEMENT

PRODUCTION 4.0 – signifies a new role for industrial robots, reporting systems and data analysis, systems reporting media costs, and production cycle management systems. The new challenge is integrating these areas into a single system operating in one efficiency model.

We implement tools and philosophies underpinning:

PROCESS ANALYSIS, DIAGNOSIS, AND MAPPING – this represents mapping the process flow, considering time and repetition. It is often a preparation step for subsequent stages, such as building or optimizing processes.

THEORY OF CONSTRAINTS (TOC) – involves managing by eliminating bottlenecks. It assumes that even the most complex system or process has one limitation that determines the efficiency of the entire system or process. Once identified and improved, the focus shifts to the next constraint.

LEAN MANAGEMENT – represents a system and philosophy for managing production processes and the entire organization. Lean involves learning by doing and problem-solving management. It includes work standardization, pull systems, lean production, addressing the seven types of waste (7M), 5S, Kanban, SMED, Genchi Gembutsu, TWI, quality circles, etc.

ORDER TRAINING: Lean Management

KAIZEN – “Even the longest journey begins with a single step” – Lao Tse. Kaizen is a key part of Lean processes and means continuous improvement by taking small steps and addressing problems at their source.

DEMING CYCLE – PDCA – the principle of continuous improvement: Plan, Do, Check, Act.

REFERENCES: “We had been planning the relocation of our plant (steel element production), including the installation of a new production line, for several months. After conducting a tender and verification discussions, we chose 4VALUE® Business Consulting to carry out the process. Diagnosing the current state and planning the processes in the new location were combined with implementing Lean Management in the company. 5S, SMED, OEE, and other LEAN tools were integrated with a new approach to management.”

“Nearly two years of collaboration with 4VALUE® Business Consulting allowed us to navigate the entire process very efficiently while simultaneously increasing employee engagement. The experience and professionalism of 4VALUE consultants, along with the program for owners: Virtual Board Member®, enhanced our managerial and leadership competencies, showed us how to solve everyday operational problems, and provided significant support in making important decisions.”

I highly recommend 4VALUE® Business Consulting and look forward to continued fruitful cooperation.” Krzysztof Brzęczek – CEO and Owner, AKWIB Sp. z o.o.

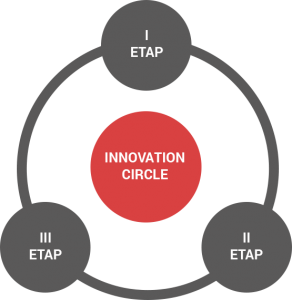

OPTIMIZATION CIRCLE – the program involves building a flywheel of optimization and innovation in the company to establish a natural cycle of repetitive actions that independently drive the company’s development.

ACTION METHODOLOGY – proper methodology is a crucial element of every process. Without proper diagnostics, understanding the company’s interior, its values, problems, operations, and key people, no process can be carried out effectively. Our methodology, based on extensive experience, encompasses all elements necessary for properly conducting efficiency processes (see also: action methodology).

A part of these projects also includes employee training processes. Based on a detailed analysis of the company’s situation, we can create customized training programs for specific personnel groups – managers, team leaders, and staff.

A critical element of any change is supporting key people after its implementation – that’s why we offer assistance through our program – Virtual Board Member® – a permanent consulting program for Owners and Boards.

Another type of process optimization is REORGANIZATION

Companies operate in various ways: by business lines, customer segments, geographical regions, technological platforms, matrix, or functional structures. Each area can undergo restructuring or optimization. What is the simple difference?

RESTRUCTURING:

- Involves changing the structural model of the company, defining how the company’s authorities group resources, coordinate actions, achieve goals, and fulfill functional roles.

- It is recommended that at least 5 years separate one restructuring from the next, as studies show a significant temporary decline in efficiency before returning to growth.

Restructuring caused an average profitability decline of 2.6% (Fortune 50 list, small and large European companies, study by Stephane J.G. Girod, Samina Karim, HBR – May 2017).

OPTIMIZATION:

- Focuses on increasing efficiency, adding value, improving processes, and splitting, transferring, or resolving business units without modifying the company’s core structure.

- Prolonged cycles showed a much smaller temporary decline in efficiency compared to restructuring and delivered long-term growth.

SEE ALSO: Company Strategy building Program

INVITATION: Paweł Haponiuk